Published by Manufactured Assemblies Corp. | Contract Manufacturing Experts Since 1976

When you’re sourcing wire harness manufacturing for your next project, the difference between success and costly delays often comes down to choosing the right manufacturing partner. Whether you’re developing prototypes for a new product launch or scaling production for an established line, understanding what separates reliable contract manufacturers from the rest can save you time, money, and significant headaches.

What Makes Wire Harness Manufacturing Complex?

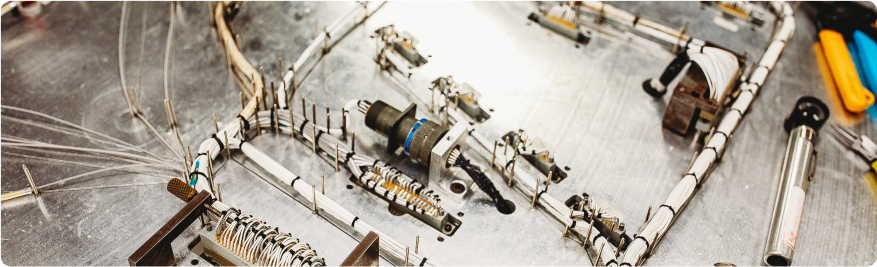

Wire harness and cable assembly manufacturing involves much more than simply connecting wires. Modern applications require precision engineering, quality materials, and manufacturing processes that can accommodate everything from simple connections to complex electromechanical sub-assemblies with hundreds of connection points.

The challenge intensifies when you factor in industry-specific requirements. Automotive harnesses must withstand extreme temperatures and vibrations. Medical device assemblies require biocompatible materials and strict contamination controls. Aerospace applications demand components that perform reliably in harsh environments while meeting stringent weight requirements.

5 Critical Success Factors in Wire Harness Manufacturing

1. Rapid Prototyping Capabilities

Speed to market often determines product success, especially in competitive industries. The best contract manufacturers offer quick-turn prototype services that can take your concept from design to working prototype in days rather than weeks.

Look for manufacturers who maintain in-house engineering teams capable of design for manufacturability (DFM) analysis. This expertise helps identify potential production challenges early, preventing costly redesigns during full-scale manufacturing.

2. Scalable Manufacturing Processes

Your manufacturing partner should seamlessly transition from prototype quantities to full production volumes without compromising quality or delivery timelines. This requires sophisticated production planning, inventory management, and quality control systems.

Consider manufacturers who have experience with both low-volume, high-mix production and high-volume standardized manufacturing. This flexibility becomes crucial as your product lifecycle evolves.

3. Quality Assurance and Testing Protocols

Reliable wire harnesses and cable assemblies are critical to end-product performance. Your manufacturing partner should implement comprehensive testing protocols including:

- Continuity testing to verify all connections function correctly

- Insulation resistance testing to ensure proper isolation between circuits

- High-voltage testing for applications requiring electrical safety certification

- Pull testing to validate mechanical connection strength

- Environmental testing for temperature, humidity, and vibration resistance

4. Supply Chain Management and Component Sourcing

Material availability can make or break production schedules. Experienced contract manufacturers maintain relationships with multiple suppliers for critical components, helping ensure consistent material availability even during supply chain disruptions.

The best partners also offer component engineering services, helping you select materials that balance performance requirements with cost considerations and long-term availability.

5. Regulatory Compliance and Certification

Many industries require specific certifications for wire harnesses and cable assemblies. Whether you need UL listing, FDA compliance, or aerospace certifications, your manufacturing partner should have experience navigating these requirements.

This includes understanding documentation requirements, maintaining proper material traceability, and implementing quality management systems that support regulatory compliance.

Common Wire Harness Manufacturing Challenges (And How to Avoid Them)

Challenge: Late Delivery Due to Design Issues Solution: Partner with manufacturers offering design for manufacturability review and prototype validation before production begins.

Challenge: Quality Problems During Production Scaling Solution: Choose manufacturers with proven quality systems and experience scaling similar products.

Challenge: Component Availability Issues Solution: Work with partners who maintain strategic inventory and have diverse supplier networks.

Challenge: Cost Overruns During Production Solution: Ensure accurate quoting based on detailed specifications and clear change order processes.

Key Questions to Ask Potential Manufacturing Partners

Before selecting a wire harness manufacturer, consider these critical questions:

- What is your typical lead time for prototypes and production runs?

- Can you provide references from companies in our industry?

- What quality certifications do you maintain?

- How do you handle design changes during production?

- What is your approach to supply chain risk management?

- Do you offer value engineering services to optimize costs?

Making the Right Manufacturing Partnership Decision

Successful wire harness manufacturing projects result from partnerships where both technical capabilities and business practices align with your needs. The lowest-cost provider isn’t always the best choice when you factor in the total cost of quality issues, delays, or communication problems.

Look for manufacturers who demonstrate expertise in your specific application requirements, maintain robust quality systems, and have the capacity to grow with your business. The right partner becomes an extension of your engineering team, contributing valuable insights that improve both product performance and manufacturability.

Next Steps for Your Wire Harness Project

When you’re ready to move forward with wire harness or cable assembly manufacturing, start by clearly defining your technical requirements, quality standards, and timeline expectations. The more detailed information you can provide to potential manufacturing partners, the more accurate their proposals will be.

Consider reaching out to multiple manufacturers to compare capabilities, but focus on partners who ask detailed questions about your application rather than those who immediately provide generic quotes. The best manufacturing relationships begin with manufacturers who take time to understand your specific challenges and requirements.

Remember that successful contract manufacturing is ultimately about partnership. Choose a manufacturer who demonstrates genuine interest in your project’s success and has the technical capabilities, quality systems, and business practices to deliver consistently reliable results.

Need expert wire harness or cable assembly manufacturing? Manufactured Assemblies Corp. has delivered reliable contract manufacturing solutions since 1976. Contact our engineering team to discuss your project requirements and learn how our proven processes can help ensure your project’s success.