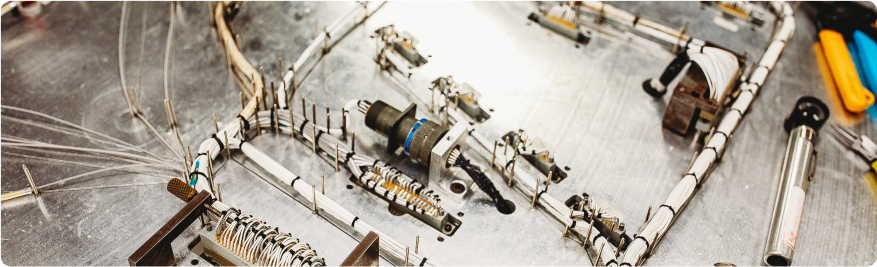

Build It Right. The First Time.

In demanding industries— medical devices, aerospace, renewables, and automation— wire and cable harness assembly performance directly impacts system uptime and reliability. These seven best practices will help ensure your assemblies are built to last, built to spec, and built for results.

1. Know Your Environment

Before choosing materials, document all conditions:

- Temperature

- Humidity

- UV exposure

- Vibration

2. Use Certified Connectors

Connectors are critical failure points. Choose quality:

- MIL‑DTL, IP67 ratings

- Secure mating, tight tolerances, follow manufacturers guidelines and test

Avoid cheap imports—poor contacts cost more in the long run.

3. Balance Shielding and Flexibility

- Braided = strong EMI protection, less flex

- Foil = flexible, lightweight

- Hybrid = best of both

Match shielding to your environment and signal type.

4. Choose the Right Stranding

- Fine-stranded = high-flex applications

- Solid-core = low-loss, long-run power

Stranding impacts durability, ampacity, and bend radius.

5. Prevent Crosstalk

Power and signal lines don’t mix well.

- Separate noisy and sensitive lines

- Use foil barriers or grounded shields

- Follow IPC/WHMA-A-620 layout best practices

Clean layout = clean signal.

6. Add Mechanical Protection

- Heat-shrink boots

- Over-molded junctions

- Strain reliefs and grommets

These touches prevent field failures—and boost durability.

7. Test and Track Everything

Don’t ship it if you haven’t:

- Checked continuity

- Run hipot/insulation resistance

- Labeled and logged test results

Document every step. Your quality system will thank you.

Final Word: Build for the Mission

Your assemblies are only as strong as their weakest point. These best practices help prevent failures before they start. At MAC, we help engineers spec, prototype, test, and build assemblies that perform under pressure—every time.

Need a custom cable assembly for your next project?

Let’s talk. Contact us →